Anti-corrosive paint is a kind of paint that can be used on the surface of the object to protect the inside of the object from corrosion. It is a kind of paint commonly used in industrial construction. It is widely used in aviation, shipbuilding, chemical industry, chemical industry, oil pipeline, steel structure, bridge, oil drilling platform and other fields, and is favored by the majority of industrial engineering manufacturers.

Kinds of anti-corrosion paint

There are many kinds of anti-corrosion paint, according to the composition can be divided into: epoxy, polyurethane, acrylic, inorganic, chlorinated, rubber, polyethylene anti-corrosive paint; according to the use can be divided into: pipe, ship, metal, furniture, automobile, rubber; according to the solvent can be divided into: water-based paint, oil anti-corrosion paint.

Anticorrosive paint, also known as anti-rust paint, is a type of paint that is designed to protect metal surfaces from corrosion or rust. It is widely used in various industries, including automotive, aerospace, marine, and construction, to prevent metal structures and equipment from deteriorating due to exposure to harsh environments.

Corrosion is a natural process that occurs when metal surfaces are exposed to moisture, oxygen, and other environmental factors. This can lead to the gradual breakdown of metal structures, resulting in structural damage, loss of strength, and even failure. Anticorrosive paint helps to prevent this process by providing a protective barrier between the metal surface and the environment.

Anticorrosive paint works by forming a protective layer on the surface of the metal, preventing moisture and other corrosive agents from reaching the metal surface. The paint is formulated with special additives that make it resistant to corrosion, and it can be applied to a range of metal surfaces, including steel, aluminum, and iron.

Types of anticorrosive paint

There are different types of anticorrosive paint available, each with its own unique properties and advantages. Some types of anticorrosive paint are designed for use in harsh marine environments, where metal structures are exposed to saltwater and other corrosive agents. Others are designed for use in high-temperature environments, where metal structures are exposed to extreme heat and oxidation.

Anticorrosive paint can be applied using various methods, including brush, roller, or spray application. The type of application method used will depend on the size and complexity of the metal structure being painted.

Overall, anticorrosive paint is an essential product for maintaining the integrity and durability of metal structures and equipment. Its use can prevent costly repairs and replacements, and ensure that metal structures remain safe and reliable over time.

Effect of Anticorrosive paint

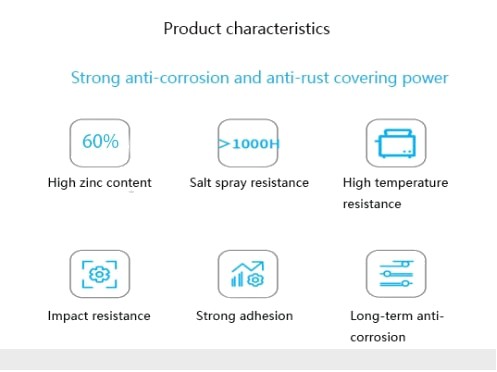

Protective effect: metal, wood, concrete and other materials are often exposed to the atmosphere, due to the erosion of atmospheric water, salt spray, gas, acid and alkali substances, microorganisms, and gradually destroyed. The heavy anti-corrosion coating can isolate these substances and prevent corrosion, thus playing a protective role and extending the service life.

Corrosion inhibition: in the anti-corrosion coating layer contains chemical anti-rust pigments, when there is water, can dissociate corrosion inhibition ions from these anti-rust pigments, these ions can also make the corrosion of the battery electrode polarization to inhibit the corrosion. Therefore, the corrosion inhibition can make up for the lack of shielding effect, and in turn, the shielding effect can prevent the loss of corrosion inhibition ions, so that the corrosion inhibition is stable and lasting.

Decorative role: paint with bright, beautiful, bright and gorgeous, color and other characteristics, heavy anticorrosive paint can change the original color of the object, harmonize the color, improve the environment, beautify life. In national defense, the protective color of the paint is also used to play a hidden role.

The role of the logo: on the ship's various pipelines, mechanical equipment, signaling and other heavy anticorrosive paint as a symbol, can make the operator easy to identify and operate. Transportation lines are also painted with different colors to indicate warnings, dangers and other signals.

Heavy anti-corrosion paint

Heavy anti-corrosion coatings are paints used to protect metal materials such as steel from corrosion by chemical media or chemical fumes. The heavy anticorrosive coating is a kind of anticorrosive coating, which can be applied in a relatively harsh corrosion environment compared with conventional anticorrosive coatings.

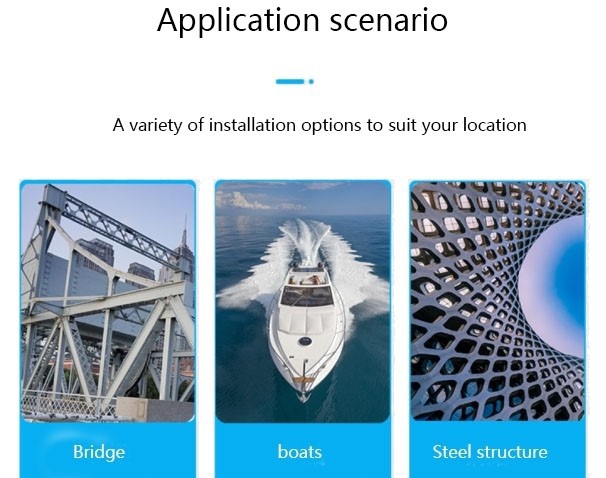

1. Large-scale industrial and mining enterprises: chemical, petrochemical, iron and steel and large-scale mine smelting pipelines, storage tanks, equipment, etc.;

2. Important energy industries: natural gas, oil pipelines, oil tanks, power transmission and transformation, nuclear power equipment and coal mines;

3. Modern transportation: Bridges, ships, containers, trains and automobiles;

4. Emerging offshore engineering: offshore facilities, coastal and bay structures and offshore oil drilling platforms.

Surface preparation:

Ensure that the coating surface is clean, dry and free of grease, dust and other contaminants. Sandpaper or mechanical treatment if necessary to enhance the adhesion of the coating.

Primer treatment:

In some cases, it may be necessary to first apply a primer to enhance adhesion, provide additional protection, or improve the appearance of the coating.

Paint mixing:

Carefully stir the heavy anti-corrosion paint to ensure that the colors and ingredients are evenly mixed.

Construction method:

Brush: Apply the paint evenly with the appropriate brush in the recommended painting direction and method.

Roll coating: Use a roller for coating to ensure that the paint evenly covers the entire surface.

Heavy coating: Coating drying Depending on product specifications and application conditions, the coating is allowed to be fully dried and cured at the recommended temperature and humidity.

Depending on the needs and recommendations, it may be necessary to apply multiple layers of paint to achieve the desired anti-corrosion effect and coating thickness.

Cleaning and maintenance:

After completion of construction, clean the painting tools and working areas in a timely manner, and carry out regular maintenance and inspection as required. When applying heavy anticorrosive paint, it is important to follow the product's safety and use instructions, ensure that proper personal protective equipment is used, and work in a well-ventilated environment. In addition, the appropriate construction methods and technologies should be selected according to the specific application needs and conditions of the coating surface to ensure the best painting effect and performance.

Surfaces to provide long-term protection against corrosion and rust due to exposure to harsh environments. By forming a protective layer, it effectively isolates the contact between the metal surface and air and water, slows down the chemical reaction process, and extends the service life of the metal component. Suitable for a variety of envirCorrosion and rust resistant paint is a paint designed for metal onments, including high humidity, salt spray, chemical corrosion and other conditions. In addition, anti-corrosion and anti-rust paint not only improves the durability of the structure, but also improves the appearance and increases the color choice, so that it can protect the function at the same time, but also meet the decorative needs. Therefore, it is widely used in Bridges, ships, automobiles, buildings and other fields, and is an indispensable and important means to protect metal structures.

Our so-called heavy anticorrosive coatings are actually used in corrosive environments such as the sea, and the protection period of heavy anticorrosive coatings is also higher than that of ordinary anticorrosive paints, and heavy anticorrosive coatings are obviously superior to ordinary anticorrosive coatings in the application range, and have a high commercial position in the paint market.

Heavy anti-corrosion coatings must meet the following conditions

1, can be used under harsh conditions, and can be long-term anticorrosion, in the Marine environment and chemical pollution serious places can also be long-term anticorrosion, anticorrosion time to ensure more than 10 years, even in the case of acid and alkali resistance medium water with a certain temperature, can also be used for more than 5 years.

2, thick film is an important sign of heavy anticorrosive paint. During construction, the dry film thickness of normal coatings is between 100 and 150μm. Heavy duty anticorrosive coatings will be 50 to 100μm higher than it. Of course, there are higher ones such as 1000 or 2000μm.

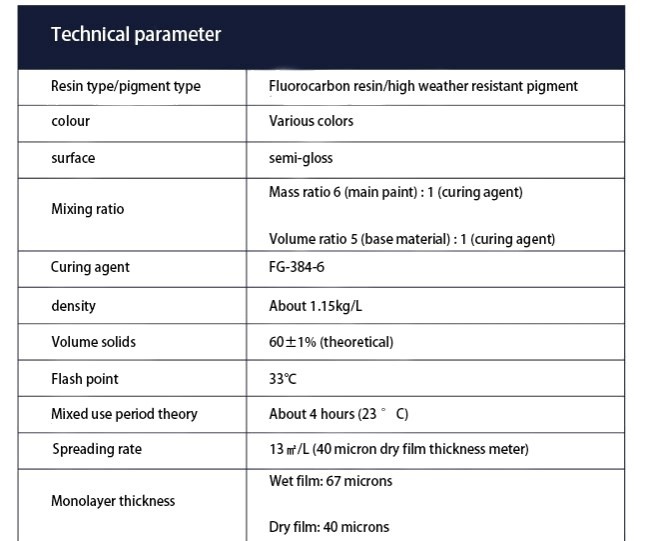

Epoxy coatings, polyurethane coatings and fluorocarbon coatings are common on the market. If you want the performance and effect of the paint film to be better, the general matching effect is good.

Dongguan Superior Chemical Co., Ltd. is one of the few domestic R & D, production, sales in one of the professional production of high-end industrial coatings enterprises. Products include reflective paint, glow-in-the-dark paint, fluorescent paint, mechanical paint, heavy anti-corrosion paint, floor paint, putty, engineering machinery paint, advertising paint and other industrial coatings, products are used in a variety of mechanical equipment, steel structure, road engineering, hydropower engineering, automotive industry and general industry and other fields, key sub-fields include: Road reflection, construction machinery, automobile painting, electric power equipment, etc. 13 categories, now has a number of engineering cooperation cases, during the period by the industry and the same praise.

The company's network operation headquarters is set up in Dongguan, in the paint industry through the ISO:9001:2000 quality management system, ISO:14025-III environmental management system and China environmental label products and other certifications

Q: What is anti-corrosion and anti-rust paint?

Q: What is the working principle of anti-corrosion and anti-rust paint?

Q: How to choose the appropriate anticorrosive paint?

Q: Can anti-corrosion and anti-rust paint be painted by hand?

Q: Does the coating of anti-corrosion and anti-rust paint require special preparation?

Q: How long is the drying time of anti-corrosion and anti-rust paint?

Q: What is the coverage area of anti-corrosion and anti-rust paint?

Q: Do I need primer for anti-corrosion and anti-rust paint?

Q: Can anti-corrosion and anti-rust paint cover old paint?

Q: What are the storage conditions of anti-corrosion and anti-rust paint?

Q: What is heavy anti-corrosion paint?

Q: What are the main components of heavy anti-corrosion paint?

Q: What is the working principle of heavy anti-corrosion paint?

We're well-known as one of the leading anticorrosive paint manufacturers and suppliers in China. Please rest assured to buy the best anticorrosive paint at competitive price from our factory.

Epoxy Ester Primer, Anticorrosive Paint, Zinc Rich Epoxy Primer